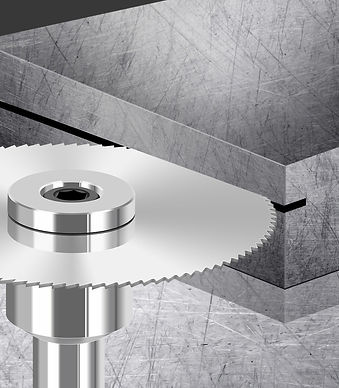

Qu'est-ce qu'une Fraise-scie carbure monobloc ?

La scie circulaire en carbure monobloc est fabriquée en carbure monobloc (également appelé « carbure cémenté » ou « acier au tungstène ») et est principalement utilisée pour la réalisation de rainures et de découpes de précision sur des fraiseuses CNC.

Les lames de scie circulaire en carbure monobloc sont largement utilisées dans l'informatique, l'électronique, les moteurs électriques, le textile, la fabrication de machines-outils et d'outils, etc.

Pourquoi le carbure ?

Comparées aux matériaux HSS, les lames de scie en carbure offrent une durée de vie plus longue et des temps de cycle réduits. Elles offrent également une dureté élevée et une longue durée de vie. Elles permettent ainsi un fraisage à grande vitesse et une grande efficacité d'usinage. Les rainures fraisées sont dimensionnellement précises et offrent une finition soignée, garantissant ainsi une qualité de produit élevée. Elles sont largement utilisées pour le fraisage et le rainurage du bois, du cuivre, de l'aluminium et d'autres matériaux difficiles à usiner tels que l'acier ordinaire, l'acier trempé, l'acier à roulement, l'acier inoxydable, l'alliage de titane, etc.

Quels matériaux peuvent être découpés avec des Lame de scie circulaire en carbure monobloc ?

-

Alliages de cuivre, de laiton et de bronze

-

Autres alliages de métaux non ferreux

-

Bois/plastiques non métalliques

-

Acier ordinaire

-

Acier trempé

-

Fonte

-

Alliage de titane

Lame de scie circulaire en carbure monobloc ToolingBox Série TC10/TC20

ToolingBox propose des lames de scie circulaire en carbure monobloc des séries TC10/TC20 adaptées à différents secteurs, notamment le travail du bois, les machines-outils, l'industrie légère, la quincaillerie, les circuits imprimés, l'industrie du verre, etc. La série TC10 est conçue pour la découpe du bois, du plastique et des métaux non ferreux, tandis que la série TC20 est conçue pour la découpe de l'acier. N'hésitez pas à nous contacter pour toute question concernant nos lames de refendage

POURQUOI NOUS CHOISIR ?

Qui sommes-nous ?

Nous sommes passionnés par la fourniture de scies à refendre en carbure monobloc de haute qualité à nos clients, de la matière première au produit fini, et nous nous engageons à résoudre tous les problèmes de rainurage et de mortaisage. ToolingBox est fier de son équipe de professionnels comptant en moyenne 20 ans d'expérience. Nous vous accompagnons de la conception à l'application finale, en passant par la production et le réaffûtage.

WHY US?

Avantages de nos Lame de scie circulaire en carbure monobloc

Ébauches en carbure de haute qualité

Fabriqué à partir de carbures de haute qualité, durable et longue durée de vie.

Dentelé et pointu

L'angle des dents est spécialement conçu et le processus de meulage rend les dents plus tranchantes.

Finition double miroir

La surface de la lame de scie est lisse dans une petite tolérance pour maintenir la qualité de coupe et une efficacité élevée.

Plusieurs options de spécifications

pas grossier et fin avec des dimensions en pouces et en métriques, différentes épaisseurs peuvent être proposées

Cas d'utilisation et application des Fraise-scie carbure monobloc

1. Comparaison des scies à refendre HSS et carbure

L'étude de cas montre que lors du refendage de matériaux abrasifs tels que la fonte ou les alliages aluminium-silicium (Si > 10%), la durée de vie des scies à refendre en carbure peut atteindre 8 à 10 fois celle d'une lame de scie à refendre équivalente en HSS, et le temps de cycle d'usinage sera également réduit à 1/4 de celui des scies à refendre en HSS.

2. Cas d'utilisation de Lame de scie circulaire en carbure monobloc

Ce cas montre que les Lame de scie circulaire en carbure monobloc ToolingBox série TC20 offrent une excellente durée de vie (environ 200 fentes) avec une vitesse de coupe raisonnable (80 m/min) lors du refendage de pièces d'axe en acier allié.

Étapes de sélection des Lame de scie circulaire en carbure monobloc

01

Sélectionnez le diamètre extérieur

En général, le diamètre extérieur est sélectionné en fonction de la profondeur de coupe (tableau 1).

03

Déterminer l'épaisseur

Déterminer l'épaisseur de la lame de scie en fonction des besoins de coupe (tableau 2)

02

Sélectionnez le diamètre intérieur

Trouvez le trou intérieur correspondant en fonction du diamètre extérieur (tableau 2)

04

Pas grossier ou fin ?

Si vous travaillez avec des métaux non ferreux, ToolingBox suggère des scies à pas grossier et à pas plus fin pour les métaux ferreux.

*Dia Sizes larger than 100mm need to be customized!

Tooth Forms and Tooth Geometry:

Tooth form A with face similar DIN 1837 (fine teeth) ;

For low cutting depths, slots and thin-walled tubes with small diameter and for short broken chips.

Tooth form B with face similar DIN 1838 (large teeth) ;

For solid material, deep cuts, tubes with wall thickness above 2,5 mm and long broken chips.

Contactez-nous directement pour obtenir un devis pour une demande B2B ou une vente en gros